Modeling what happens in the combustion chamber as accurately as possible is very important in the design of more environmentally friendly aircraft engines. New "unsteady" models are now being used to better simulate the formation of pollutants as well as the ignition or extinction phases of these engines.

Number 46

|

|

By 2020, new aircraft are going to have to emit 80% less nitrogen oxides and consume half the fuel than is the case today. An immense challenge for engine manufacturers who will need to completely alter their engine designs. It won’t be possible to build hundreds of engines and test them one by one: they are going to have to be modeled. But the production of pollutants, such as nitrogen oxides, is complex as it depends on the temperature and the time that the gas remains in the engine. This cannot be reproduced with the current computation methods so new models will have to be developed. This is the aim of the Mogadir project launched in 2006.

|

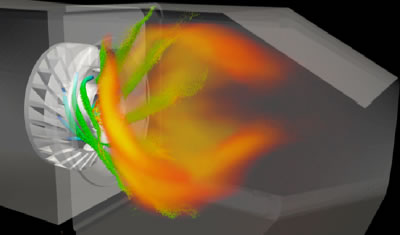

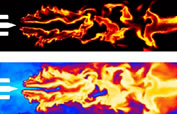

Instantaneous fields for OH mass concentration and temperature. The case of a cryogenic flame – the Mascotte experiment at Onera-Palaiseau DEFA computation executed using the CEDRE package |

"Stationary models deal with flows that generally do not change over time explained Philippe Villedieu, researcher at the Aerodynamics and Energetics Modeling Department (DMAE) at Onera in Toulouse. Now, during the ignition phase the flows and chemical reactions change very quickly, they aren't stationary at all. This is also true of turbulent flows where the large-scale vortex structures move constantly and in an unpredictable fashion". Hence the need to develop “unsteady” physical models and numerical methods that can be used to calculate the results of these models. |

|

To take into account fluctuations in the speed of the flows we have to work at scales that are much smaller than those we have been using previously. Modeling vortices requires a finer mesh that that used for modeling mean flow. But computation times then need to be longer so we have to be clever. "The principle is to create an unsteady model, but simplified, with a quite large mesh size, but not too large. But as we can’t use this to describe very small scale phenomena we have to add a second model for what happens within each mesh component. Using this method means we can establish, for example, the concentration of species of minority chemicals such as nitrogen oxides or carbon monoxide, without computing them directly". |

|

|

The results are good. "We can simulate a part of the combustion chamber, and we have compared these results with those of experiments on the M1 test bench at Onera-Palaiseau, explained the researcher. In this way we have been able to validate our calculations". There are still some difficulties, such as simulation of the fuel injection. This is in the form of the finest possible droplets, but no current software is able to model the formation of these droplets. |

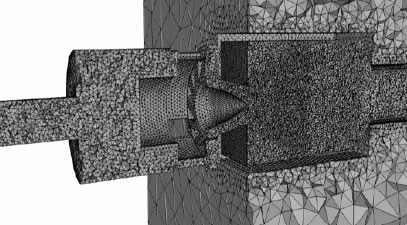

Mock-up of a sector of a combustion chamber mounted on the M1 test bench at Onera-Palaiseau |

|

So, in their calculations, research workers have to resort to experimental data for these droplets. Simulation of the injection system will also require new models and more computing resources. Once the models are verified they are made available to other Onera teams, or industrial partners such as Snecma and Turbomeca.

|

|