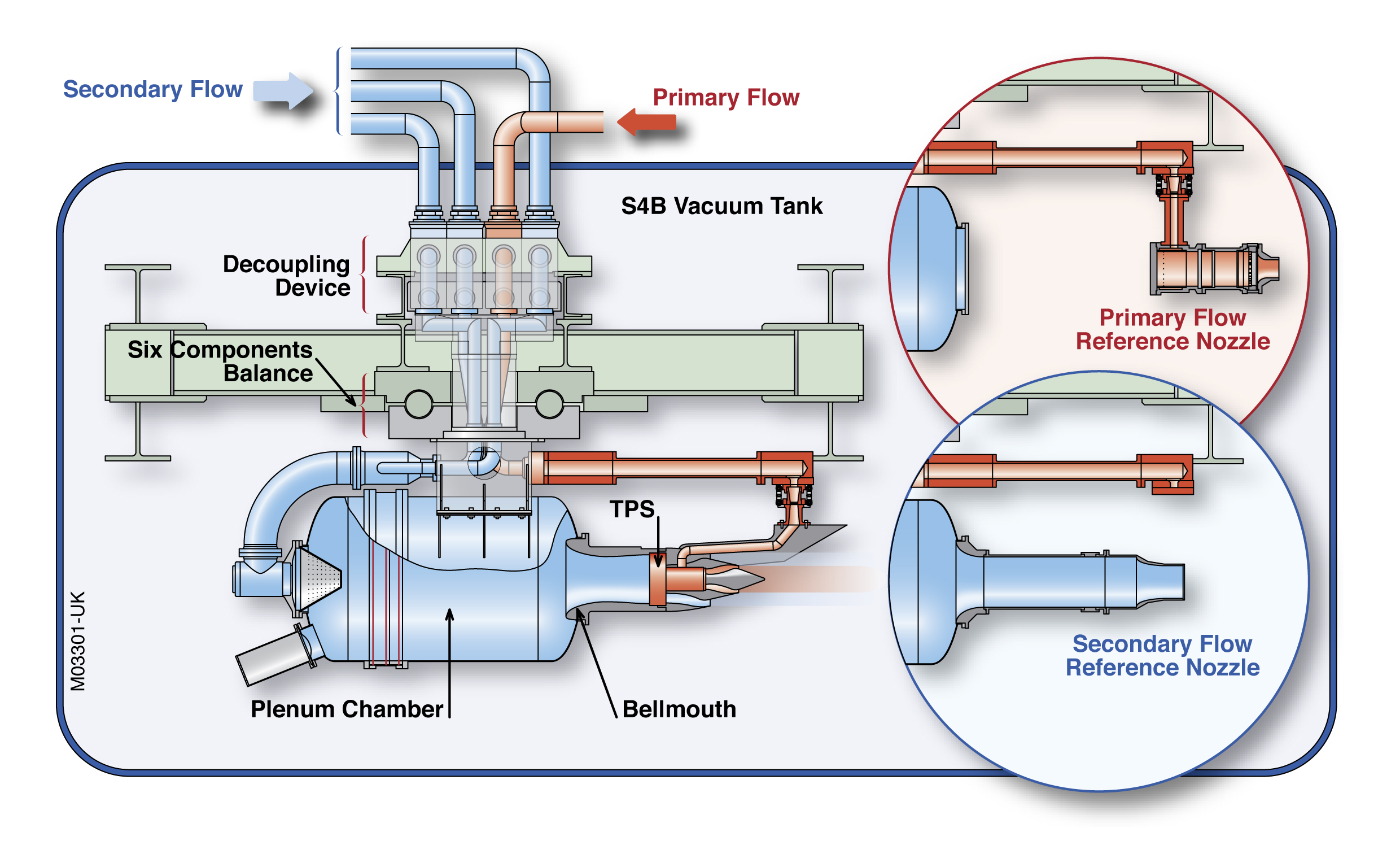

Model Engine Calibration Rig

TYPICAL TEST

- Nozzle thrust tests with altitude simulation.

- Direct or reverse jet model engine calibration, with simulation of the wind tunnel test conditions.

- Through Flow Nacelles calibrations.

- Thrust reversers calibrations and jet angularities.

S4B vacuum tank

- Cylindrical sealed vessel, diameter 2.5 m, length 15 m.

- Fed by compressed air:

- two pressure levels, 9 bar and 64 bar;

- dry and clean air (12 µm mesh filtering, less than 5 mg of water per kg of dry air) with temperature controlled;

- air storage: 9,500 m3 at 9 bar and 109 m3 at 270 bar.

- Vacuum connection:

- internal absolute pressure level from 15 mbar to atmosphere;

- connection pipes (diameter up to 1,200 mm) toward vacuum tanks with adaptable volume between 1,000 and 8,000 m3;

- possible vacuum setting by ejector effect (Bertin ejector or using the tested nozzle itself).

TEST TECHNIQUES

- Mass flow control and temperature control of the two jets.

- Separate control of the pressure upstream of the fan, of the model engine RPM and of the nozzle exit pressure.

- Test rigs checking using reference nozzles.

- Jet thrust vector measurement (module and angularity).

MEASUREMENT

- Steady measurements = 64 analog channels, 16 bits A/D converter, digital lowpass filtering with a bandwidth from 0.01 to 10 Hz. Steady accuracy ±1 mV, resolution 0.3mV.

- On demand, unsteady measurements = 64 analog channels at 100 kHz per channel. 12 bits A/D converter, digital lowpass filtering with a bandwidth from 0 to 20 kHz (if necessary the number of channels can be increased).

- Steady pressures = 992 channels (by DTC PSI®, system 8400).

Measurement techniques

- Temperature measurement by thermocouples and PT100 probes

- Load measurement by ONERA six components balances (decoupling device for air flow crossing through).

- Sonic throat mass flow meters for the primary and fan jets.

Accuracy:

- The uncertainties in the 4" test rig with the Ø 100 mm reference nozzle are (from test campaigns between 1987 and 2009),

- Flow coefficient: ± 0,1 % in 86 % of the test cases,

- Thrust coefficient: ± 0,15 % in 81 % of the test cases.