A first at Onera: the successful testing of an injector with a technology new in Europe - a double "Swirl" supplied with liquid oxygen /liquid methane. This technological progress was implemented on Onera’s cryogenic test bench Mascotte, located in Palaiseau (October 2011).

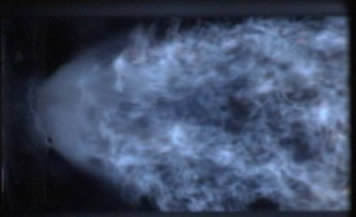

LOX/LCH4 combustion – Point-in-time Image (exposure time 1/16000)

For cryogenic engines, the replacement of liquid hydrogen with liquid methane has definite advantages, especially related to its much higher condensation temperature, close to that of the related propellant - Oxygen (around 100K versus 20K under engine conditions), which facilitates the use. Its higher density is also an asset, because it allows for significant reduction of the tank size.

The goal is to reduce the cost of space launches, in particular by reducing the volume of the tank, and by using simplified cryogenic technology, an easier filling process and a simplified cooling system for long flight duration time.

The double swirl is a technique that consists in rotating the propellant sprays, in order to optimize the mixture for combustion.

Engines of this type intended for space propulsion (last stage of the launcher, orbit change, interplanetary flights) had not yet been built and tested in operational situations.

This injector is a potential candidate to equip a rocket engine combustion chamber, operating at 10 bar. It was designed and manufactured by ONERA in close collaboration with the DLR, Snecma and EADS Astrium, its partners for this activity within the framework of the European ISP-1 (In space Propulsion) program.