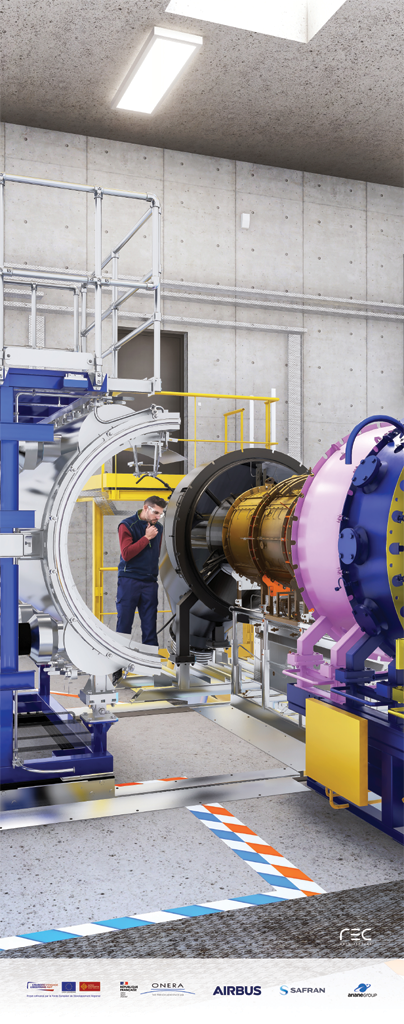

General perspective of the PyCoFiRe facility attached to the LACOM (Multiphasic Combustion Laboratory)

What is PyCoFiRe ?

PyCoFiRe (Pyrénées Composite Fire Research) is a new test-facility designed to assess the environmental performance and fire behaviour of aircraft new materials. Officially launched on December 8, 2021, on the ONERA Fauga-Mauza site, by Bruno Sainjon, CEO of ONERA, Slawomir Tokarski, Director of European Territorial Cooperation and Nadia Pellefigue, Vice-President of the Occitanie Region in charge of Higher Education, Research, Europe and International Relations, this collaborative research laboratory will be unique in the world and will replicate the real use conditions of aeronautical components.

Answer to a need

Lightening aircrafts and improving the fire resistance are two objectives of the increasing use of composite materials. In addition, the development of new means of engine fires extinguishing systems is an environmental issue and one of European strategic objectives to which this program provides a response in conjunction with the economic sector. As a collaborative project, PyCoFire will serve both European and French aeronautical manufacturers.

European funding, a regional choice

The European Regional Development Fund (FEDER) Midi-Pyrénées Garonne 2014-2020 adopted on December 2, 2014, by the European Commission, is a major tool at the service of regional development. The Occitanie Region has chosen to devote €10 million from this fund to the PyCoFiRe project on behalf of the EU.. PyCoFiRe project key feature: such challenges for greener aviation have been anticipated since 2018.

PyCoFire received financial support from Airbus, Ariane Group and Safran. These three industrial partners were stakeholders in the definition of the facility requirements and will be the first users.

Technical presentation

PyCoFiRe will consist of two test simulators. The FAN simulator, measuring 2.4 meters of external diameter, is designed to mimic the annular compartment located behind the engine nacelle cowls of an aircraft. The CORE simulator replicates another annular compartment (1.4 meters of external diameter) located in a deeper fire area within the engine near the combustion chamber.

360° immersive view of the FAN simulator

360° immersive view of the CORE simulator

Project management group

- Architect: REC Architecture

- Civil engineering office: SERIGE

- Construction Economist: COSECO

Project management assistance services

- Consulting office for the Environment Protection Classified Facility requirements compliance file: EODD

- Safety Prevention Health Coordinator: Bureau VERITAS

- Technical control office: SOCOTEC

- Geotechnical studies: GFC

- Works purchaser: BPANTET

Building works

- Lot 1 « Earthwork »: Société Nouvelle Thomas & Danizan

- Lot 2 « Big works»: Seg-Fayat

- Lot 3 « Iron works»: COM.ACMD

- Lot 4 « Electricity + Heating Ventilation air Conditioning »: Fauché + Kalitec

- Power electricity: SNEF

Technical assistance to ONERA

- CapGemini

Temporary consortium of equipment sub-project companies

- Representative of the consortium, management of the sub-project, interfaces with civil engineering and design/manufacture of test assemblies: DB VIB ingénierie

- Instrumentation and control/command: SPIE industrie et tertiaire

- Regulation of process fluids: CLAUGER

- Industrial piping methods: SPIECAPAG Régions France

Contact : Gillian.Leplat @ onera.fr