- ONERA

- Scientific Departments

- DMAS - Materials And Structures

- Research units

DMAS - Research units

EPIC | M3S | MS2 | MC2 | CRD | LEM | SIAM

Manufacturing process, Imaging & Health monitoring (EPIC)

The research studies carried out in our team consist in developing multiphysical models and innovative experimental approaches in order to:

(1) manufacture organic or ceramic structural and multifunctional materials and assess their thermophysical properties under room temperature as well as extreme conditions;

(2) provide non-destructive diagnoses of materials and structures right after their manufacturing and ensure their health monitoring over time.

Our scientific works are based on experimental facilities gathered in research labs dedicated to:

- manufacturing of organic-matrix, ceramic-matrix composites and monolithic ceramics,

- scanning electron microscopy (SEM) and X-ray crystallography,

- non-destructive inspection (NDI) and structural health monitoring (SHM),

- nanoindentation and microhardness testing.

Moreover, several of our research activities require the thermomechanical test benches supported by the TECH research unit.

a. oxide-oxide ceramic matrix composite structure

b. ceramic sample manufactured by direct laser additive manufacturing

c. ZGP nonlinear optical crystal

d. quantitative compositional mapping of a metal alloy under SEM

e. non-destructive imaging of microcracking of a coated ceramic-matrix composite using Flying Spot thermography

f. guided waves imaging of impact damage in a composite sample using Laser vibrometry

g. detection of cracks in a metallic turbine blade using vibrothermography

h. laser-induced damage in an elastomer sample, at 800°C

i. numerical simulation of the microcracking of a coating under thermal loading

j. in situ SEM imaging of the propagation of a crack under micromechanical loading

k. digital image correlation imaging of the propagation of a crack under 2,000°C

l. nanoindentation print

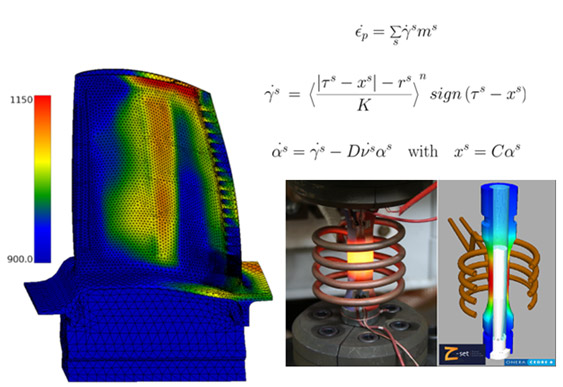

Mechanics of Metallic Materials (M3S)

M3S investigates the non-linear behavior and integrity of metallic materials and structures in the aerospace domain when they are submitted, in use, to severe multiaxial and/or thermo-mechanical loads. With the objective of constantly improving the design process, the unit conducts research to model the manufacturing part processes in order to assess their impact on the fatigue service life. The modeling is based on strong interaction with experimental mechanics, ranging from fine characterization of the physical mechanisms up to the development of multi-instrumented technological tests with the purpose to validate new proposed approaches on representative test structures.

Technological fatigue tests with heat gradient of surfaces for validating the modeling tools

(behavior law and damage model) which are developed for estimating the service life of a

high-pressure turbine blade

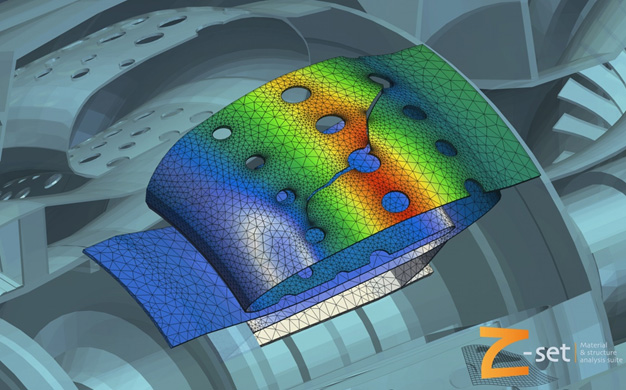

Computational structural mechanics unit (MS2)

The researchers of the Computational Structural Mechanics (MS2) unit develop algorithms, mathematical models and innovative computational solutions concerning mechanics of materials and structures. Its field of activity covers the following scientific topics: structural dynamics, multi-scale approach of failure, stochastic phenomena, optimization, multi-physical numerical simulation, high-performance calculation, surrogate model, applied mathematics, coupled experimental-numerical studies, etc.

Numerical simulation of crack propagation, conducted with Z-set/Z-cracks, in an

aeronautical engine combustion chamber under thermo-mechanical fatigue loading

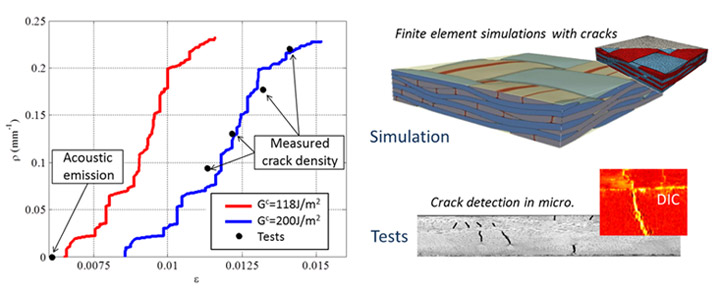

Modeling and mechanical characterization of composites (MC2)

The research work conducted by MC2 aims at proposing constitutive equations to predict the behavior, damage and fracture which are specifically developed for composite materials, such as laminates with unidirectional plies or 3D woven materials. To improve the insight into the damage and failure mechanisms, MC2 is interested in the experimental characterization methods for composite materials using multi-instrumented tests on samples and structures, and also in the development of tools to ensure consistency between tests and simulations. Lastly, the advanced design activities for composite structures focus on the optimization of stacking sequences taking account manufacturing constraints, as well as topological optimization for composite structures.

Forecasting crack density on mesoscopic scale in 2D Glass/Epoxy woven composite and experimental validation

Design and dynamic resistance (CRD)

The activities of the unit can be broken down into two distinct aspects:

The activities of the unit can be broken down into two distinct aspects:

- Numerical simulation of the crash and impact strength of aeronautical structures combined with the development of experimental tools and methods. These tools and methods aim at studying the dynamic behavior of materials and structures at high deformation speeds (modeling of impactors such as ice, bird, tires, etc.), and fluid-structure coupling in order to improve numerical simulations.

- Development of new aeronautical structure concepts comprising, on the one hand, the development of numerical tools for predicting structural mass balances for evaluating in the early design phase the relevance and feasibility of new aircraft concepts and, on the other hand, the development of technological solutions (active materials and structures).

Crash tower: 15 m tall drop tower for full-scale aeronautical structures crash testing

Laboratory for microstructural investigations (LEM)

LEM, a joint CNRS-ONERA research unit, conducts fundamental research aimed at establishing the link between physical mechanisms operating at the small scale and the macroscopic behavior of materials (non-equilibrium microstructures; mechanical, electronic, optical properties, etc.). The approach combines experiments (synthesis, electron microscopy, X-ray diffraction), theoretical developments, and modeling on different scales (electronic structure, atomic-scale simulations, phase field methods, dislocation dynamics).

These activities are spread across two areas:

- Microstructures: morphology, plasticity and transport

- Small-sized carbon and boron nitride-based materials

LEM is also in charge of the renewal and updating of the fleet of transmission electron microscopes to meet the evolving needs of all researchers working at ONERA.

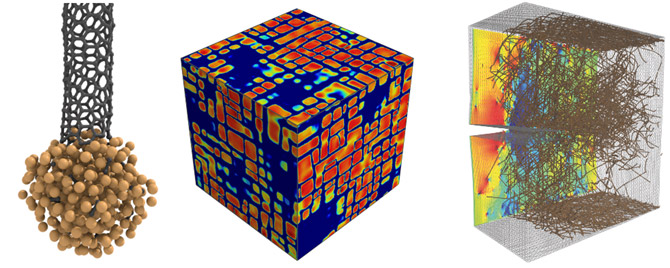

Modeling microstructures: growth of a carbon nanotube, nickel-based superalloy, crack-front plasticity

Sciences and Engineering of Metallic Materials (SIAM)

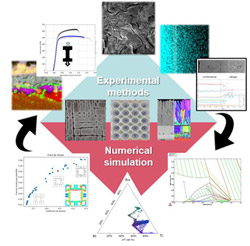

SIAM unit investigates design, study and development of metallic material systems for aerospace. Combining experimental methods and numerical simulations, based on thermodynamic and physico-chemical models, the activities aim at understanding the process-microstructure/architecture-properties relationships and their evolutions in complex environment (high temperature, oxidation/corrosion, lifetime, ...).

SIAM unit investigates design, study and development of metallic material systems for aerospace. Combining experimental methods and numerical simulations, based on thermodynamic and physico-chemical models, the activities aim at understanding the process-microstructure/architecture-properties relationships and their evolutions in complex environment (high temperature, oxidation/corrosion, lifetime, ...).

From the research of new alloy compositions to the design of coatings and architectural systems, the unit exploits data through optimization and machine learning techniques in order to accelerate the design of the systems studied. The work carried out by the unit is based on numerous experimental means: a surface treatment and thermal post-treatment laboratory including oxidation/corrosion benches, as well as physical and chemical characterization laboratory.