Testing Capabilities

- ONERA

- Wind Tunnels

- Testing Capabilities

- BD2 : Nozzle thrust measurement

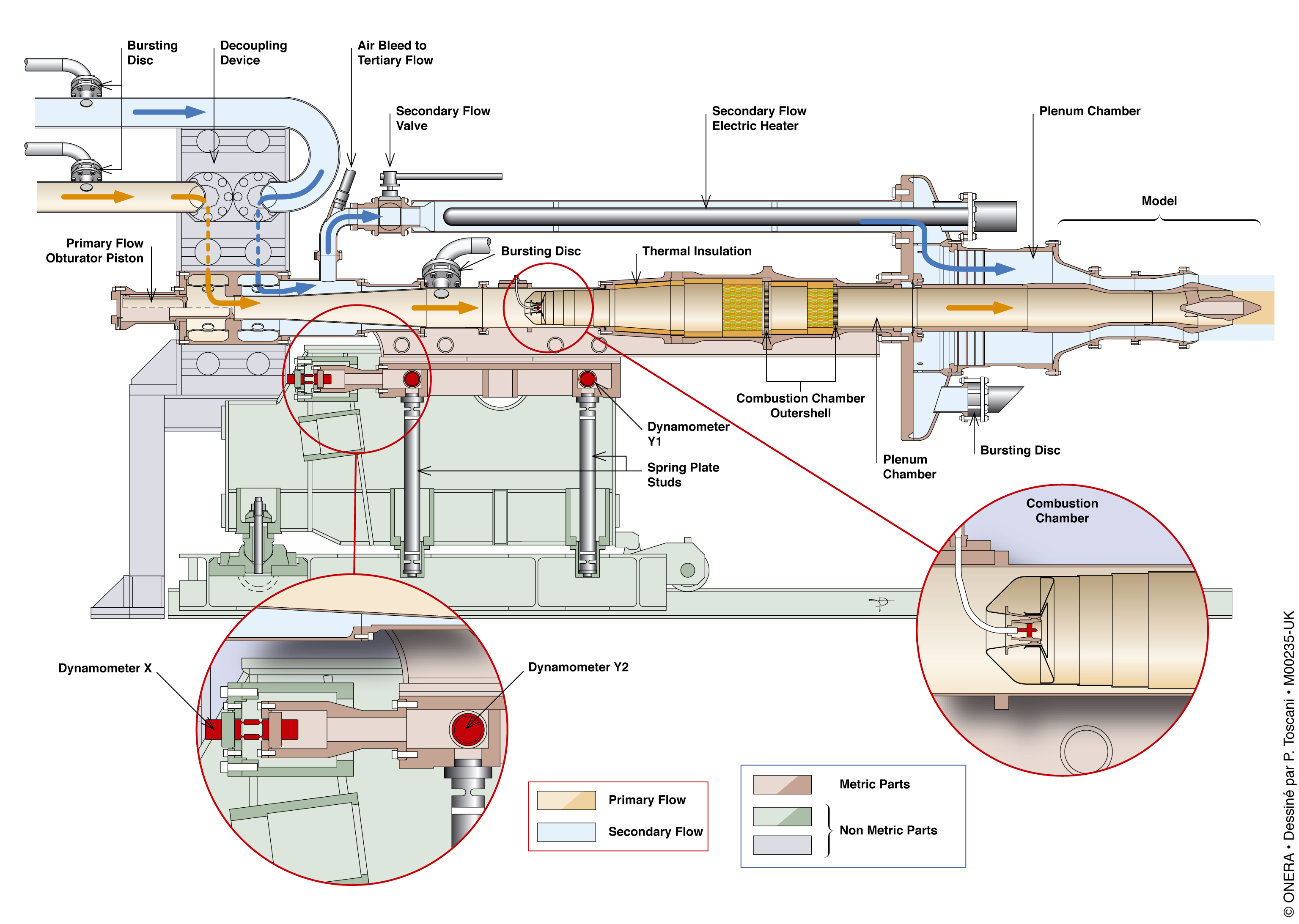

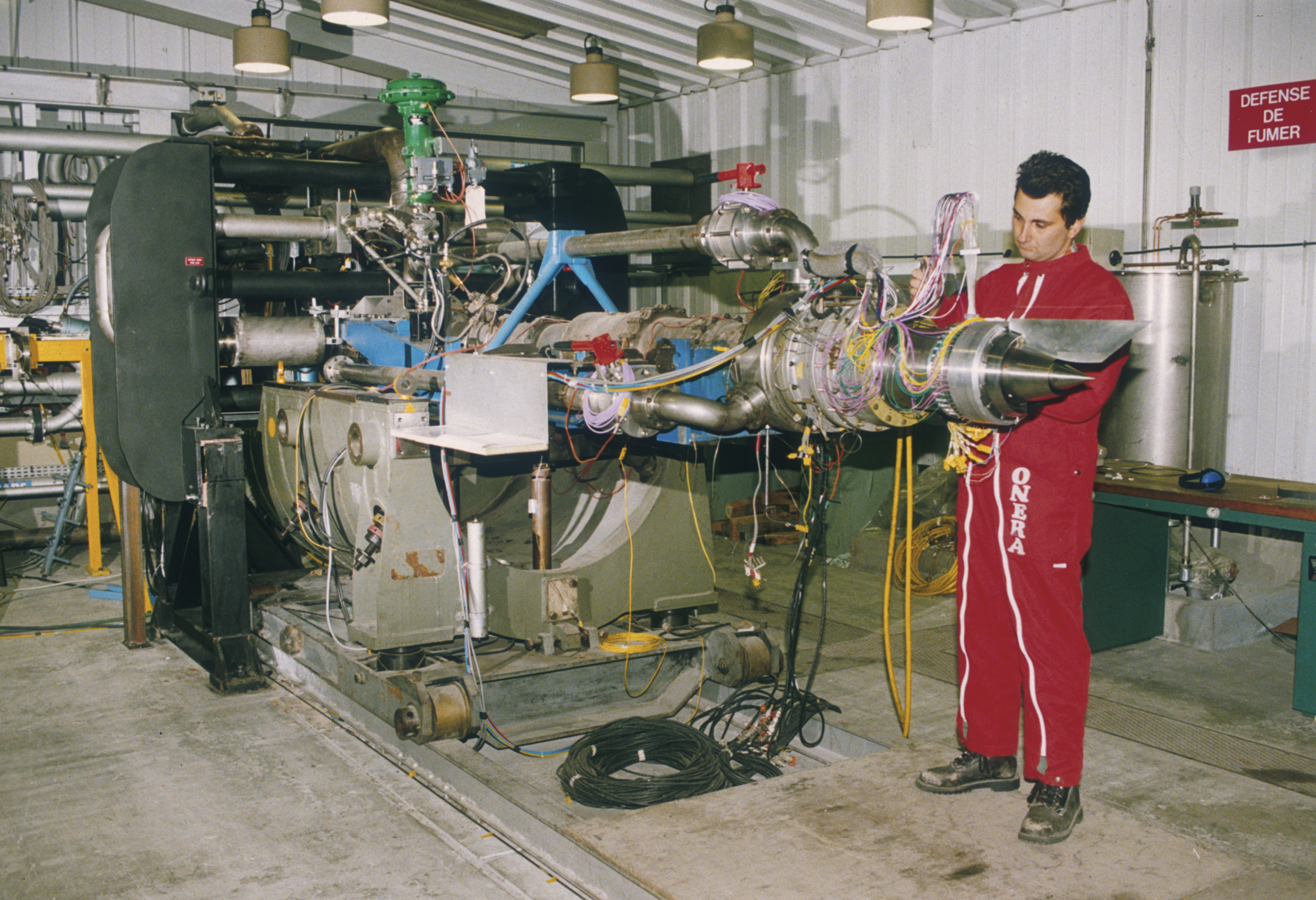

BD2 : Nozzle thrust measurement

Direct-jet and reverse-jet engine nozzle and afterbody performance characteristics.

Thrust measurement, mass low rate, pressure and distributions on single-flow and bypass-flow models of various scales

Typpical tests

- Nozzles or engine after bodies performance (mass flow, thrust).

- Flow mixers (pressure and temperature maps at different distances downstream the nozzle exit).

- Thrust reversers jet angularities.

Test techniques

- This is a blow down test stand with usable air storage of 3,500 kg, the blow down time depends on the maximum mass flow rate through the model.

- Depending on the flow rates, 6 to 8 blow downs can be run per day.

- The primary and secondary expansion ratios are controlled independently.

- Outlet jet probing capability (pressure and temperature maps at different distances downstream the nozzle exit).

- Outlet jet visualization capability by carbon gas injection in the internal flow.

- Flow angularities can be measured either by probing or by laser velocimetry.

- Infrared signature.

Characteristics

- Forces range:

- dynamometer thrust capacity: 9,000 N ;

- lateral component of the thrust capacity: 1,200 N.

- Flows range:

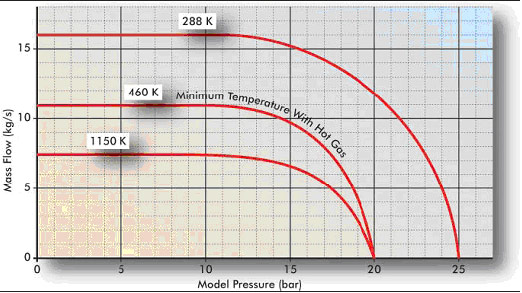

- primary flow range, 16 kg/s maximum mass flow rate in cold condition, maximal temperature 1,150 K allowed by the stand structure (see the mass flow vs pressure diagram) ;

- secondary flow range, 16 kg/s maximum mass flow rate in cold condition, and 1.5 kg/s maximum at 450 K.

Measurements

- Steady measurements = 96 analog channels, 16 bits A/D converter, digital lowpass filtering with a bandwidth from 0.01 to 10 Hz. Steady accuracy ±1 mV, resolution 0.3mV.

- Unsteady measurements = 64 analog channels at 100 kHz per channel. 12 bits A/D converter, digital lowpass filtering with a bandwidth from 0 to 20 kHz (if necessary the number of channels can be increased).

- Steady pressures = 992 channels (by DTC PSI®, system 8400).

- Primary flow measurement: hot or cold mass flow rate by sonic throat mass flow meters, when hot flow, kerosene mass flow is measured by piston mass flow meter.

- Secondary flow measurement: hot or cold mass flow rate by sonic throat mass flow meters upstream of the heater.

- Laser velocimetry, IR signature and visualizations on request.

Accuracy:

- thrust: ≤± 0.15 % of the calibration range,

- lateral thrust component: <± 4 %,

- mass flow: ≤± 0.1 %.