Ceramics are still surprising us

Ceramics have been a little neglected recently but they still have something to reveal to us: the latest generations of eutectic" ceramics are very promising for engines, while ceramic composites – more traditional – have had a new lease of life with the development of low-cost processes.

"

Number 34

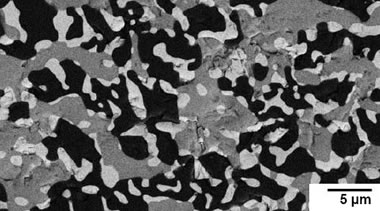

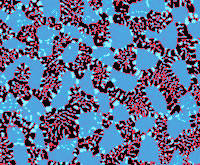

The microstructure of a ternary alloy (with 3 components), studied to increase its toughness, i.e. its resistance to the propagation of cracks in order to reduce fragility. |

The reduction of consumption and pollution is today a priority for the whole of the aeronautic industry and ceramics may be able to play a role in this race for efficiency. To improve the performance of aircraft and helicopter engines, the temperature needs to be increased. But then we come up against the limits of the materials used to manufacture the engine. Most metal alloys are unable to resist temperatures greater than 1,100° C, and ceramics are fragile. "In the eighties, we had high hopes for ceramic matrix composites; that is, ceramics reinforced with fibers", recalls Michel Parlier, researcher at the Department of composite materials and systems at Onera. "But the results were disappointing: the mechanical characteristics were not as good as we'd have liked, and the cost was too high". | ||

|

That is why Onera is working on designs for new high performance materials, oxide-based eutectic ceramics. "We are really looking for great things from this family of materials", emphasized Michel Parlier. They are a mixture of metallic oxides which, in the right proportions, melt together at a temperature which is slightly lower than the fusion temperature of each individual oxide. In this way ceramics are obtained in which the metallic oxides are very closely interwoven in the form of monocrystals, which gives them remarkable mechanical properties. "They are stable almost right up to the temperature of fusion, around 1700 °C for materials based on alumina (aluminum oxide), yttrin (yttrium oxide) and zirconia (zirconium oxide)", commented the researcher. |

|||

|

|||

|

|||

|

Cécile Michaut, scientific reporter. |

|||